OLYMPUS MICROSCOPE, REFLECTED LIGHT - BRIGHTFIELD & DARKFIELD. Reflected Light Microscope with BH2-UMA Vertical Illuminator. In addition to this Olympus BHM/BH2-UMA, Capovani Brothers Inc stocks a wide range of used upright microscopes. Typical manufacturers include American Optical, Bausch & Lomb, Leica, Nikon, Olympus. VARIOUS COMPONENTS OF THE MODEL BHM. The Olympus System Microscope for reflected light Model BHM consists of a modular, building-block system of various components and interchangeable accessories, as shown below. A wide variety of combinations, standard or optional, is available according to your requirements.

The BHM microscope that I bought recently was fitted with a light source that was an incandescent bulb. It is driven by a variable transformer PSU. The PSU is quite nice, the bulb not so much. I have a suspicion that the bulb is a replacement that isn't quite the right voltage as it has never been more bright than a bit dim. I decided to build an LED replacement, so ordered some Cree LEDs and set about making a mount for them.I had a cylinder I had cast from some melted down scrap, and turned it to the diameter of the lamp holder that fits on the back of the microscope.

After it was the correct diameter I drilled some holes that will hold the LED into place:

The LED is then fixed in place with three screws:

The LED is then fixed in place with three screws:The cylinder acts as a heat sink. I had bread-boarded the circuit and checked how hot the circuit and LED got and it doesn't get very hot at all. It's a 1W LED so there's not a lot of scope for dissipation. The connections for the LED run in a milled channel down the cylinder. I put a block of aluminium on the end as a mounting plate for the circuitry and as extra heat-sinking outside of the light holder.

The PSU outputs a.c. which is fine for the bulb but not so good for the LED. I added a bridge rectifier, some dropper resistors and a capacitor to convert the a.c. to a d.c. supply. This mounts on the block on the end of the assembly. Initially I used bits of wire to connect the circuitry to the PSU:

3D printed stand-offs hold the circuit board away from the aluminium block:

I wasn't very happy with using bits of wire to connect the PSU and didn't fancy hunting around for a suitable connector, so I made one. I turned a couple of pins from phospher bronze:

And 3d printed a shell in two parts. The pins have a shoulder that holds them in to the shell. The pins turned out nicely:

Here's the light in place and generating photons. The LED is positioned very close to the position the bulb filament would have been in and I end up with a pretty even illumination across the field of view.

Olympus Bhm Microscope

I may add bolts to hold the connector together, but the pins are a tight fit so I may not. Here's the original bulb in it's holder as a comparison:

The LED leads are soldered across a capacitor for now, I'll tidy them up later. Once I've run this for a while I'll make a PCB to mount the components anyway, so this is probably temporary.

The LED leads are soldered across a capacitor for now, I'll tidy them up later. Once I've run this for a while I'll make a PCB to mount the components anyway, so this is probably temporary.I've got a descriptive video of this LED illumination here:

The BHM Metallurgical Microscope

Robert R. Pavlis

Girard, Kansas USA 66743

Several years ago I purchased an Olympus BHM metallurgical microscope. I have used this instrument very regularly since then. This is a discussion of both this instrument and metallurgical microscopes in general.

Many microscopes are designed to be modular—that is they can be converted for different types of microscopy by simply changing a few parts. The requirements for metallurgical microscopes are so dramatically different from other microscopes, however, that manufacturers generally produce special dedicated metallurgical microscopes, rather than have modules available to convert other instruments.

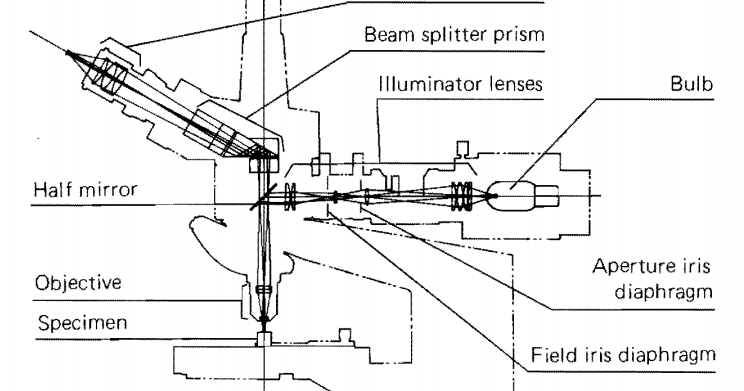

Metallurgical microscopes are designed for observation of the surfaces of (usually) opaque materials. Thus there is absolutely no need for the optically complex sub stage illumination system present on other microscopes. However, these instruments must have an equally complex epi illumination system.

The special illumination system needs to be built so that the light can be sent either directly down the objective or through light channels surrounding the objective to give the epi illumination equivalent of bright field and dark field illumination respectively. These instruments always produce a somewhat 'washed out' image with bright field illumination, because the illuminating beam is passing through the same lens that is used for observation. The lenses thus need to be both high quality and clean! This same type of optical arrangement is commonly used for fluorescence microscopy, except here the wavelength that is used for excitation is removed by filters in the microscope head, so this problem does not arise.

The two images below show the Olympus BHM instrument with the head removed. It is a bit difficult to see on the images, but the image on the left has the light channel in position to bring the light beam down through the objective that is being used. The image on the right has the light channel so that light is passed through special channels around the objective. The small slide at the lower right of each image is used to switch between light paths. Note that it is OUT on the left image and IN on the right one.

The image below this text shows an Olympus Neo 20X objective. Notice how much larger its diameter is compared to normal objectives. Notice the three light channels around the lens. On close inspection one can see light coming up through the channels.

Contrary to popular opinion, the intensity of the light source, if properly designed, need not be much brighter than for standard microscopy. Most modern instruments use quartz halogen illumination.

Metallurgical microscopes still need a stage—but it normally can be a simple solid metal plate. However, because it is often necessary to place thick specimens on the stage, the stage needs to be adjustable so that it can be moved up and down on the focusing rack and pinion. (The Olympus BHM is designed to work this way.)

The image below shows the stage area of the Olympus BHM that is being described here. Instead of a normal slide holder, there is a simple rectangular aluminium plate. This image also shows how the objectives have a much larger diameter than those on normal microscopes.

Metallurgical microscopes must have their objectives corrected for use without cover slips. In addition, they also need to be designed to have the light channels around the lenses as discussed earlier. Because these objectives are larger than standard, they obviously require special turrets and nose pieces.

The optical requirements for heads and oculars for these instruments are no different than for any other optical microscopes. Unfortunately those are about the only parts these instruments have in common with other instruments.

These instruments are the best choice whenever observations need to be made of flat opaque surfaces. Contrary to popular opinion, these instruments can be useful for observation of many types of biological specimens. However, because of the designation 'metallurgical', there is a tendency to avoid using them for this purpose, even when ideal biological applications arise.

Sometimes these instruments are referred to as 'Inspection microscopes'. A great many of them are used for examination of industrial parts—especially in the semi-conductor industry. The available used instruments of this type tend to have been well maintained. They generally were also made to very high standards in the first place. Furthermore, the heavy use of these instruments by industry has resulted in an abundance of used instruments. This they are often available at very affordable prices.

Olympus Bhmj

The Olympus BHM that I acquired several years ago came with three of the special metallurgical objectives with light channels around the lenses and an adaptor that allowed normal objectives to be screwed into the nose piece. The three Olympus metallurgical objectives provided 5X, 10X, and 20X. A few months later I was able to obtain a 40X objective belonging to the same series.

The instrument was in excellent condition when it arrived. However, oddly, virtually every screw in the instrument was loose! This was really odd. Some had come out completely and were loose inside! It took about an hour to tighten all the loose screws and to find the ones that had come loose and put them in place. The instrument was provided with its original illumination system. The power supply was not provided, but I already had one that was very suitable.

I quickly came to the conclusion that I did not like the orange coloured illumination that one gets with all varieties of tungsten filament lamps. It was particularly unacceptable when used at lower intensity. The solution to this problem was obvious—get rid of the standard light source and put in the highest power white LED available. This was described in theJune 2006issue of Micscape. I use this instrument quite frequently, and the LED illumination has always been highly satisfactory—much better than the orange cast from the original quartz system.

The company that had owned the microscope had a special machined holder to hold the part that they examined with this instrument. I replaced this with a rectangular piece of aluminium.

Many people collect old microscopes with the goal of returning them to their original condition. That is NEVER my goal. My goal is to make them into the best possible instrument. That sometimes is original condition, but often it is not!

Using The BHM Metallurgical Microscope

In theAugust 2008issue of Micscape there was an article about the examination of coins. For high magnification numismatic studies these instruments are extraordinarily useful.

These microscopes are the instrument of choice whenever high power is required to examine opaque objects. The images below are taken with the BHM microscope described above using a 2X projection eyepiece and a Canon EOS 400D digital camera. (This model is also called the Rebel Xti). Unless specified otherwise the images are taken using illumination via the light channels, rather than through the objective.

The image below shows a 0.3 millimetre drill bit using the 4X objective. These bits are amazingly tiny!

The image below shows the same bit using the 10X objective

The next images show the surface of a brass microscope body cap machined on a lathe. This cap is several years old and there are large spots where oxidation has occurred. The first image is using the 4X objective.

The second image was obtained using the 10X objective:

The third image was obtained using the 20X objective:

The last image of this specimen was obtained using the 40X objective:

The image below shows an old sterling silver teaspoon. Although it looks shiny and practically like new note all the microscopic scratches in it. The 20X objective was used for this image.

The next image is the surface of a diamond coated knife sharpener, coarse grade, using the 10X objective.

The final image is the surface of a diamond coated knife sharpener, fine grade, but with through the lens illumination using the same objective as was used in the above image. Digital image processing was used here to remove the contribution from light scattered in the objective.

Although these types of microscope are somewhat uncommon, they can provide dramatically different optical capabilities that are not possible with other instruments!

All comments to the authors viaRobert Pavlis are welcomed.

Microscopy UK Front Page

Micscape Magazine

Article Library

© Microscopy UK or their contributors.

Published in the January 2009 edition of Micscape Magazine.Please report any Web problems or offer general comments to theMicscape Editor.

What Does An Olympus Bhm-man Analyzer Do In 2

Micscape is the on-line monthly magazine of the Microscopy UK website atMicroscopy-UK

© Onview.net Ltd, Microscopy-UK, and all contributors 1995 onwards. All rights reserved. Main site is atwww.microscopy-uk.org.ukwith full mirror atwww.microscopy-uk.net.